Introduction

CNC machines are a cornerstone in modern manufacturing, offering unparalleled precision and automation. The configuration of a CNC machine is often the determining factor in its capabilities and performance. This post aims to be your comprehensive guide to understanding different configurations of CNC machines, empowering you to make well-informed choices tailored to your unique requirements. Read Our Introduction to CNC Machining Basics

Table of content:

I. Understanding CNC Machine Configurations

A. Definition and Function of CNC Machines

CNC machines, or Computer Numerical Control machines, are automated devices that use pre-programmed sequences to control machinery and tool movements. With applications spanning industries such as manufacturing, aerospace, and automotive, CNC machines bring high levels of precision and repeatability to various machining processes.

Key Functions:

-

- Precision Machining: Allows for highly accurate and consistent parts.

-

- Automated Operation: Reduces human error and increases efficiency.

-

- Versatility: Can be adapted for a variety of machining tasks.

B. The Critical Role of Machine Configuration

Choosing the correct CNC machine configuration is not just beneficial—it’s essential for achieving the desired level of productivity and quality. The right setup will align with your project’s requirements in terms of precision, speed, versatility, and cost-effectiveness.

Considerations:

-

- Task Specificity: Is the machine specialized or versatile?

-

- Speed Requirements: How quickly do you need parts produced?

-

- Cost: What is your budget for both initial investment and operating costs?

II. Common CNC Machine Configurations

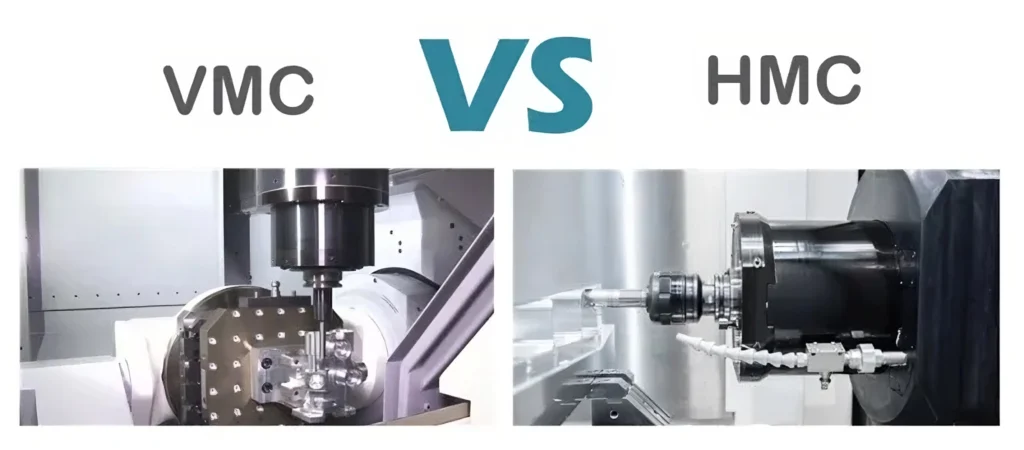

A. Vertical Machining Centers (VMC)

Vertical Machining Centers, or VMCs, feature a vertically oriented spindle. Primarily used in milling and drilling, VMCs excel in operations that require easy access to the workpiece and efficient chip removal. Read Choosing and Maintaining the Right CNC Machine for Your Needs

Pros and Cons:

| Advantages | Disadvantages |

|---|---|

| Ease of Use | Limited to 3-axis movements |

| Efficient Chip Removal | Less suitable for heavy-duty tasks |

| High Precision |

B. Horizontal Machining Centers (HMC)

Horizontal Machining Centers have horizontally oriented spindles and are optimized for heavy-duty operations like milling, boring, and tapping. HMCs can work on multiple sides of a part without repositioning, saving time and increasing accuracy.

Key Benefits:

-

- Increased Stability: Better balance and support for heavy parts.

-

- Multi-Side Machining: Can machine multiple sides without repositioning.

-

- Better Chip Evacuation: Gravity helps in more efficient chip removal.

C. Turning Centers

Turning Centers are specialized for machining cylindrical workpieces. Unlike milling machines, the workpiece rotates during the operation, allowing for intricate and precise geometries.

Applications:

-

- Manufacturing of screws

-

- Creating shafts and rods

-

- Machining of cylindrical components in automotive and aerospace industries

D. Multi-Axis Machining Centers

These advanced CNC machines can move along multiple axes simultaneously, providing unparalleled flexibility and precision. They are especially useful in industries that require complex geometries, like aerospace and medical device manufacturing.

Why Choose Multi-Axis?

-

- Reduced Setup Time: Fewer setups mean less room for error.

-

- Increased Efficiency: More operations in a single setup.

-

- Improved Surface Finish: Allows for complex geometries without repositioning.

III. Specialized CNC Machine Configurations

A. Swiss-Type CNC Machines

Swiss-type CNC machines are designed for high-precision, efficient machining of small, complex parts. They are especially prevalent in the watch-making industry but also find applications in medical and aerospace sectors.

B. Laser Cutting CNC Machines

These machines use high-powered lasers to cut through materials like metal, plastic, and even wood. They are incredibly accurate and can produce complex shapes and designs, making them ideal for industries like metal fabrication and signage.

C. Waterjet CNC Machines

Using a high-pressure water stream mixed with abrasives, these machines can cut through almost any material, making them incredibly versatile.

IV. Factors to Consider When Choosing a CNC Machine Configuration

Selecting a CNC machine is not just about the upfront cost; it’s an investment in the future of your projects and business. Consider the following factors:

-

- Budget: What is your initial investment capability?

-

- Material Types: What materials will you be cutting most frequently?

-

- Production Volume: Do you need a machine for large-scale production or small, custom jobs?

-

- Automation Level: How automated do you want the production process to be?

V. Conclusion

The configuration of your CNC machine will significantly impact its capabilities and, by extension, the success of your manufacturing operations. This guide has aimed to provide a comprehensive understanding of different CNC machine configurations, from traditional vertical and horizontal setups to more specialized options like Swiss-type and multi-axis machines. By taking into consideration various factors such as cost, materials, and production needs, you can make an informed decision that will not only meet but exceed your manufacturing requirements.

VI. Frequently Asked Questions (FAQ)

1. What is the most basic configuration of a CNC machine?

The most basic configuration would be a 3-axis CNC machine, commonly used for tasks like drilling and simple milling.

2. Are Multi-Axis CNC Machines always better?

Not necessarily. While Multi-Axis CNC Machines offer more flexibility and capability, they are also more expensive and may be overkill for simple projects.

3. Can I change the configuration of my CNC machine later?

Some aspects like software upgrades or tool attachments can be changed, but fundamental factors like axis orientation are generally fixed.

4. What types of materials can a Waterjet CNC machine cut?

Waterjet CNC machines are incredibly versatile and can cut through materials ranging from metal to stone and even glass.

5. Is a higher number of axes on a CNC machine always advantageous?

More axes provide greater flexibility but also come with a steeper learning curve and higher cost. Consider your project’s specific needs when making this decision.

6. Do specialized CNC machines like Swiss-type require special training?

Yes, specialized machines generally require operators to undergo specific training to understand their unique capabilities and limitations