Introduction

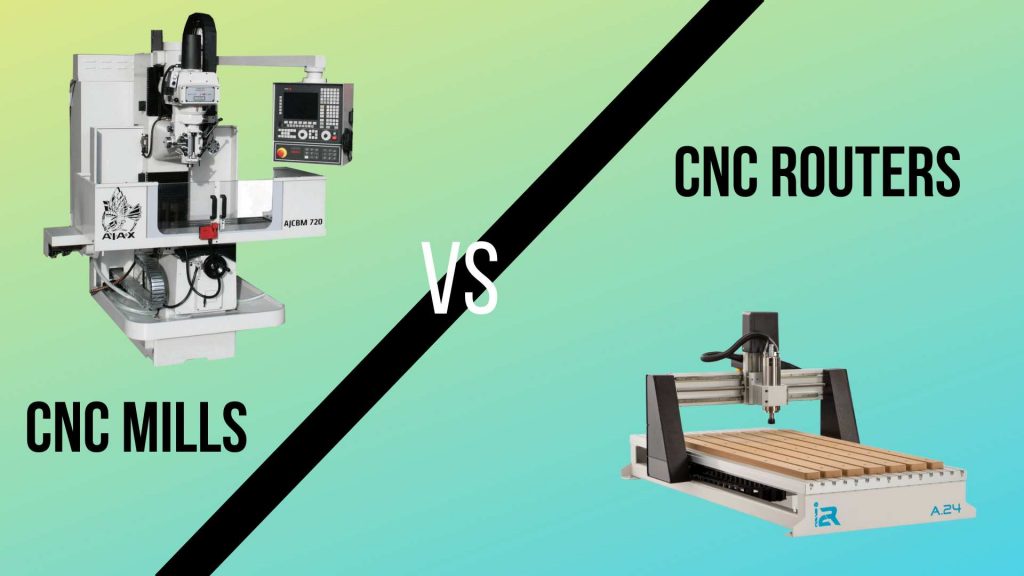

When it comes to automated cutting and shaping in the manufacturing industry, two machines often come to mind: CNC routers and CNC mills. These machines share similarities but have distinct differences that can impact your decision-making process. This comprehensive guide will dig deep into the intricate world of CNC machinery, highlighting the key differences and similarities between CNC routers and mills. We’ll explore their features, benefits, and primary applications, empowering you to make an informed decision tailored to your specific needs. Exploring Various CNC Machine Configurations : A Comprehensive Guide

Table of Contents

- What are CNC Routers?

- What are CNC Mills?

- Differences between CNC Routers and Mills

- Similarities between CNC Routers and Mills

- Which Machine is Right for You?

- Conclusion

- FAQ

What are CNC Routers?

CNC Routers, or Computer Numerical Control routers, are specialized machines designed for precise cutting, carving, and engraving tasks. Widely used in various industries, including woodworking, signage, and cabinetry, these routers offer a plethora of features.

Key Features and Capabilities

- Versatility: CNC routers excel in handling different types of materials, from softer materials like wood and foam to soft metals like aluminum.

- Routing and Engraving: These machines are particularly suited for complex projects involving intricate designs and carving tasks.

- Speed and Efficiency: With their high torque and advanced spindle moves, CNC routers complete tasks quickly, maximizing efficiency.

- Industry Applications: From furniture making to architectural design, CNC routers are designed to meet a broad range of industrial needs.

- Benefits: Improved productivity and reduced material waste are just some of the advantages of using CNC routers for your manufacturing processes.

What are CNC Mills?

CNC Mills, also known as CNC Machining Centers, are another cornerstone in the realm of automated manufacturing. Unlike CNC routers, mills are often employed in industries requiring higher precision and the ability to cut hard materials.

Key Features and Capabilities

- Material Suitability: CNC mills are designed to cut harder materials, including various types of metal and tough materials.

- Drilling and Tapping: Specialized for tasks that require precision drilling and tapping, these mills come equipped with high torque and multiple axes for enhanced accuracy.

- Accuracy and Repeatability: CNC mills offer exceptional accuracy, particularly in tasks requiring complex geometries and intricate designs.

- Industry Applications: Mills find their home in sectors like aerospace, automotive, and medical manufacturing, where precision is non-negotiable.

- Benefits: Among the key benefits of CNC mills are their versatility, excellent surface finishes, and the ability to handle complex projects with high precision.

Differences between CNC Routers and CNC Mills

Understanding the key differences between CNC routers and CNC mills is crucial for making an informed decision. Below is a table outlining the primary distinctions:

| Aspect | CNC Routers | CNC Mills |

|---|---|---|

| Principle of Operation | Move the cutting tool along three axes | Utilize rotational movement along multiple axes |

| Material Suitability | Ideal for softer materials like wood and foam | Excel at cutting hard materials like metals |

| Applications | Woodworking, signage industries | Aerospace, automotive sectors |

| Cutting Versatility | Designed for intricate carving and engraving | Suited for complex machining operations |

| Precision | Offers greater flexibility | Provides higher accuracy |

| Cost and Maintenance | More affordable and easier to maintain | Typically cost more and require more maintenance |

Factors to Consider

When selecting a machine, consider factors such as the type of materials you’ll be working with, the complexity of your projects, and your budget constraints.

Similarities between CNC Routers and CNC Mills

While CNC routers and mills have their unique features and applications, they also share some key similarities that make them invaluable in the manufacturing industry.

| Aspect | CNC Routers & CNC Mills |

|---|---|

| Control Technology | Both utilize Computer Numerical Control (CNC) technology for precise operations. |

| Automated Operation | Offer automated functionality, reducing the need for manual control. |

| Cutting Tools & Holders | Use a variety of cutting tools and tool holders for different applications. |

| Design Capabilities | Capable of creating intricate and complex designs with high precision. |

These similarities underline the versatility and adaptability of both CNC routers and mills, making them invaluable assets in various manufacturing processes.

Which Machine is Right for You?

Making the right choice between a CNC router and a CNC mill is pivotal for your manufacturing success. Here’s a more detailed breakdown to guide your decision:

Evaluating Your Specific Needs

- Materials: Your choice may largely depend on the materials you plan to cut. CNC routers excel at cutting softer materials like wood, foam, and plastics. On the other hand, CNC mills are designed to handle harder materials like metals, including aluminum and steel.

- Project Complexity: Consider the intricacy of the designs you’ll be working on. If your projects involve complex engravings or carvings, a CNC router with its high cutting versatility may be better suited. For projects requiring high precision and intricacy, especially in metals, a CNC mill is your go-to machine.

Understanding Your Production Goals

- Volume: If you’re looking at high-volume production, a CNC mill might be more appropriate due to its durability and precision. CNC routers are more suitable for smaller batches and rapid prototyping.

- Lead Times: Mills, being more precise, can sometimes take longer to complete a job. Routers, with their rapid cutting speed, might be better if quick turnaround times are crucial for your business.

Budget Considerations

- Initial Costs: CNC routers generally have a lower initial cost compared to CNC mills. This makes them a more accessible option for small businesses or hobbyists.

- Operational and Maintenance Costs: CNC mills often come with higher operational costs, including power consumption and maintenance. Ensure you budget not just for the initial purchase but also for ongoing expenses.

Expert Consultation

- Industry Insights: It’s always beneficial to consult with experts or professionals who have hands-on experience with CNC machines. Their insights could save you from making costly mistakes.

- User Reviews and Testimonials: Checking reviews and testimonials can provide real-world insights into the pros and cons of each machine type.

Future-Proofing Your Investment

- Scalability and Upgrades: Consider whether the machine can be upgraded or scaled to meet future needs. Some CNC mills offer modular upgrades, while routers might be less flexible in this regard.

- Resale Value: Machines with good resale value can be a wise investment, providing you with the option to upgrade without significant financial setbacks in the future.

By thoroughly considering these expanded points, you will be in a strong position to make the best decision for your unique needs and constraints.

Conclusion

Choosing between a CNC router and a CNC mill is no small feat. Each has its unique advantages, drawbacks, and best-use scenarios. By understanding your specific needs, production goals, and budget constraints, you can make an informed decision that will serve you well in the long term. Whether you opt for the versatility of a CNC router or the precision of a CNC mill, knowing the key differences and similarities will equip you with the knowledge to make the best investment for your manufacturing needs.

FAQ

What are the main differences between a CNC router and a CNC mill?

The main differences lie in the materials they are designed to cut and their operational principles. Routers are generally used for softer materials like wood, while mills are used for harder materials like metals.

Which is more expensive, a CNC router or a CNC mill?

CNC mills are generally more expensive both in terms of initial investment and ongoing operational costs.

Can I use a CNC router for metalwork?

While some advanced CNC routers can cut soft metals like aluminum, they are generally not suitable for hard metal work, which is better handled by a CNC mill.

What factors should I consider when choosing between the two?

Consider factors like the type of materials you’ll be cutting, the complexity of your projects, your production volume, and your budget.