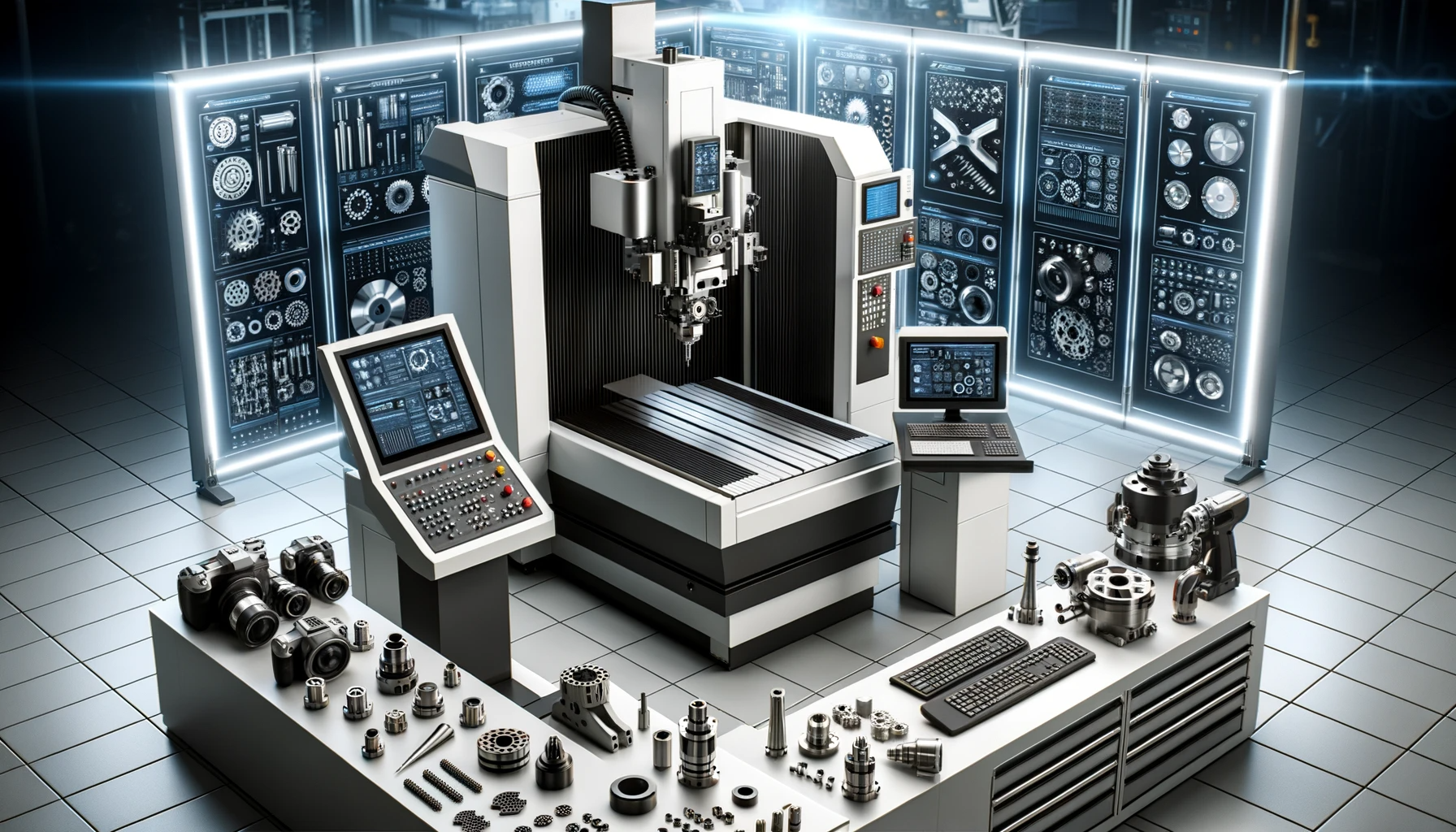

CNC machines are at the heart of modern manufacturing. Their precise operations enable the creation of intricate components that are essential in today’s industries. While the machine itself is vital, accessorizing it can dramatically enhancing your CNC machine functionality and efficiency. This article will delve into the must-have accessories that can elevate your CNC machine’s capabilities.

Key Takeaways:

- High-quality tooling and workholding accessories are crucial for precision.

- The right cutting tools ensure efficiency across different materials.

- Coolant systems prolong tool life and ensure smoother operations.

- Chip management solutions maintain a cleaner working environment.

- Probing systems significantly reduce setup time and improve accuracy.

- Software and control upgrades can modernize and streamline operations.

- Automation and robotics enhance productivity and reduce manual intervention.

Table of Contents

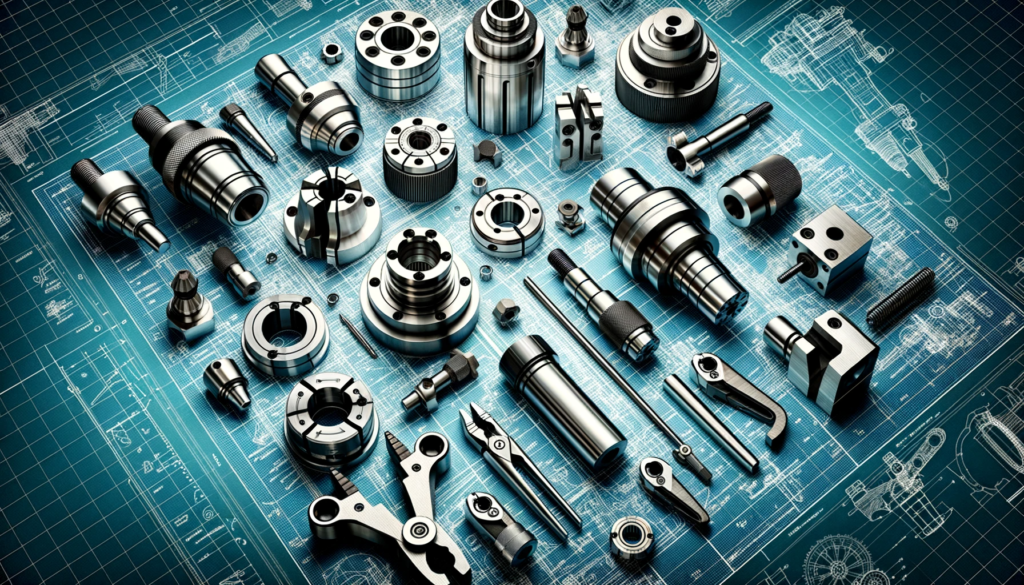

Tooling and Workholding Accessories

Ensuring that a workpiece is held securely and accurately is paramount in CNC machining. The significance of high-quality tooling and workholding accessories cannot be overstated. They are the foundation of precision and efficiency in operations.

- Tool Holders & Collets: These hold the cutting tools in place, ensuring stability during operations.

- Vices & Clamps: Used to secure the workpiece, they ensure it doesn’t move during machining.

- Chucks: Often used in lathes, they hold the workpiece in place, allowing for operations like turning.

Cutting Tools

Choosing the right cutting tools for specific materials and applications can make the difference between a successful operation and a botched job.

- End Mills: Ideal for milling operations, they come in various shapes and sizes for different applications.

- Drills: Essential for making holes in the workpiece.

- Inserts: Replaceable cutting edges used in various machining operations.

- Tool Coatings: They enhance tool life and performance, especially when working with hard materials.

Coolant Systems

Effective cooling during machining not only prolongs the tool life but also ensures smoother operations.

- Flood Coolant: Drenches the workpiece with coolant, providing extensive cooling.

- Mist Coolant: Uses a fine mist to cool and lubricate the cutting area.

- Through-Spindle Coolant: Delivers coolant directly to the cutting edge, enhancing cooling efficiency.

Read: Solutions for CNC Overheating Challenges

Chip Management

Proper chip management ensures a cleaner and safer working environment.

- Chip Conveyors: These transport the cut chips away from the machine.

- Chip Augers: Spiral devices that push the chips towards a collection point.

- Chip Bins: Collection points where the chips are stored before disposal.

Probing Systems

Modern CNC machines often incorporate probing systems to improve accuracy and reduce setup times.

- Tool Setters: Measure the tool’s dimensions and detect any breakage.

- Workpiece Probes: Used to determine the workpiece’s position and dimensions.

- Tool Breakage Detection: Ensures that the tool is in good condition before starting the machining process.

Software and Control Upgrades

Upgrading software and control systems can bring an older CNC machine up to modern standards, making it more efficient and easier to use.

- CAD/CAM Software: Assists in designing the product and generating the required machine code.

- Machine Monitoring Systems: Monitor the machine’s operations, providing data for analysis.

- Advanced Control Features: Offer more refined control over the machine, enabling more complex operations.

Automation and Robotics

Incorporating automation and robotics can drastically enhance productivity by reducing the need for manual intervention.

- Robotic Arms: These can load and unload workpieces, improving efficiency.

- Pallet Changers: Allow for the quick changeover of workpieces, reducing downtime.

- Bar Feeders: Automate the feeding of bar stock into lathes for continuous operation.

Conclusion

Accessories play a pivotal role in maximizing the capabilities of a CNC machine. By understanding and investing in the right accessories, manufacturers can ensure more efficient, precise, and productive operations. Whether it’s the tooling, software upgrades, or automation, each accessory has its unique role in enhancing CNC machining. As technology continues to advance, the accessories available will only further revolutionize the CNC machining industry.