Table of Contents

- Introduction

- Understanding the Basics

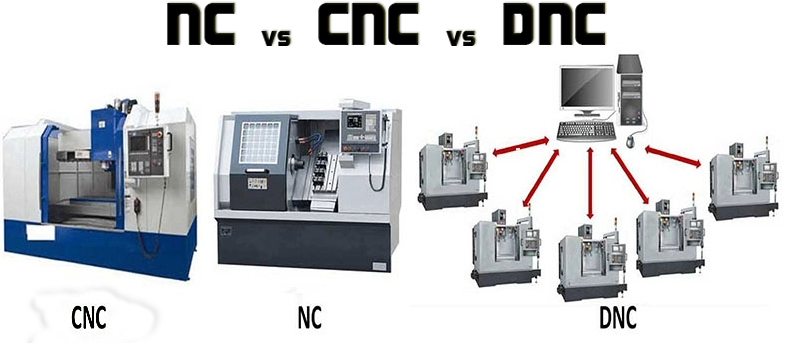

- NC vs CNC vs DNC: Key Differences

- Advantages of DNC over CNC

- Disadvantages of CNC Machines

- Components of a CNC or DNC System

- Conclusion

- FAQ

Introduction

The manufacturing realm has metamorphosed from manual interventions to intricate computer-aided machinations. Pioneering this transformation are three systems: Numerical Control (NC), Computer Numerical Control (CNC), and Direct Numerical Control (DNC). This article dissects their nuances, highlighting their advantages and limitations, guiding you through their intricate web.

Understanding the Basics

Numerical Control (NC)

An inception from the realm of “punch tape,” NC systems ushered the dawn of automation in machining. They operate on physical punch cards, driving machine actions without human intervention.

Computer Numerical Control (CNC)

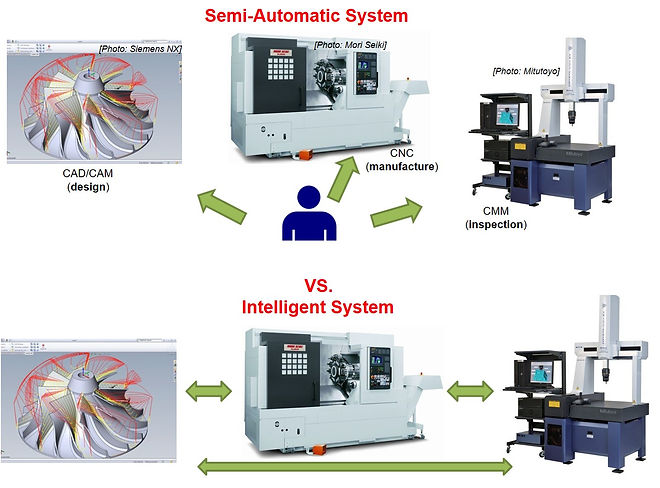

Building upon the NC foundation, CNC integrates computer-aided design (CAD) and computer-aided manufacturing (CAM). Unlike NC’s static punch tape, CNC boasts of a dynamic computer interface, accommodating real-time adjustments.

Direct Numerical Control (DNC)

DNC, a harmonious blend of its antecedents, connects multiple CNC machines to one core computer. This structure fosters seamless communication and coordination, amplifying efficiency manifold.

NC vs CNC vs DNC: Key Differences

Distinguishing these systems isn’t merely academic—it can influence purchase decisions, operational efficiency, and production outcomes:

| Criteria | NC | CNC | DNC |

|---|---|---|---|

| Control Mechanism | Operates based on pre-defined punch tape. | Utilizes a dedicated computer interface for individual machines. | Links several CNC machines, all coordinated by a single central computer. |

| Material & Task Suitability | Best for basic, repetitive tasks. | Ideal for intricate designs needing real-time adjustments. | Suitable for large operations where multiple machines need coordination. |

| Cost and Maintenance | Generally low-cost but limited in functionality. | Higher initial investment, with associated maintenance for its computer systems. | Requires substantial investment but offers centralized control, potentially reducing long-term operational costs. |

Advantages of DNC over CNC

DNC systems, while often more complex, offer several distinct advantages:

- Centralized Control: Streamline operations by managing multiple machines from a single point.

- Efficiency in Large Operations: Ideal for setups where numerous machines operate simultaneously.

- Improved Data Management: Central databases facilitate efficient data storage, retrieval, and analysis, offering insights that standalone CNC machines might not provide.

- Flexibility: Easily update or modify machine instructions without needing to adjust each machine individually.

Disadvantages of CNC Machines

Despite their precision and versatility, CNC machines have limitations:

- Cost: High initial investment, especially for top-tier models.

- Maintenance: Regular upkeep essential for optimal performance.

- Skill Requirement: Operators need training to navigate and utilize the computer interface effectively.

Components of a CNC or DNC System

Both CNC and DNC systems comprise several essential components:

- Machine Interface: The bridge enabling communication between the machine and its control system.

- Drive Motors: Propel the machine’s movement, ensuring accuracy.

- Feedback System: Monitors operations, ensuring the machine works within set parameters.

- Control Software: Dictates the machine’s movements and operations.

For a more in-depth exploration of CNC systems, consider reading our comprehensive guide on CNC machining basics.

Conclusion

In the ever-evolving landscape of manufacturing, understanding the nuances of NC, CNC, and DNC is indispensable. While each has its merits, their suitability largely depends on the specific needs of the operation. By evaluating the features and benefits of each, industries can harness the power of automation, achieving unparalleled precision and efficiency.

FAQ

Q: How has the transition from NC to CNC to DNC impacted the manufacturing industry? A: The shift has ushered in an era of heightened precision, efficiency, and automation, reducing manual intervention and errors.

Q: Is DNC more expensive than CNC? A: Initially, yes. However, the centralized control in DNC might lead to long-term operational cost savings.

Q: Can I upgrade my CNC system to DNC? A: Yes, but it requires significant modifications, including integrating a central computer system and ensuring compatibility across machines.